Products

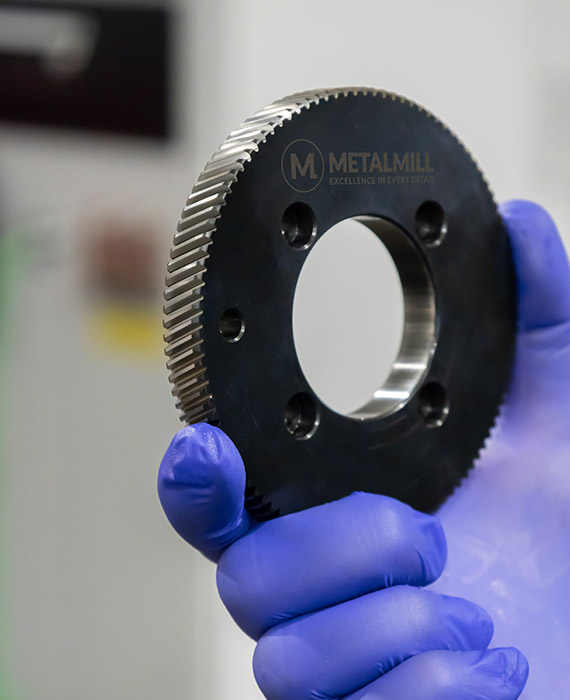

In continuous sale: magnetic cylinders, printing cylinders, counter cylinders, and gears.

Contact

Company registration details, contact information for individual departments. We are happy to answer.

METALMILL CIELESZ SP. Z O.O.

We are a small company with great potential! We love challenges and are not afraid to tackle problems head-on.

QUALITY AND PRECISION

Have always been, are, and will always be our top priority.

Have always been, are, and will always be our top priority.

PUNCTUALITY

We set the deadline individually with each client.

We set the deadline individually with each client.

MACHINE PARK

New machines – top quality.

New machines – top quality.

Extensive knowledge enables us to take on any challenge.

We work exclusively with CNC machines from renowned brands.

This allows us to maintain high precision and quality in our work. Our clients appreciate our dedication, immediate assistance, fast order processing, and the precision of our services.

Milling

We perform machining in the field of milling using machines from the renowned Mazak brand.

Shaft Grinding

All stages of rough, shaping, and finishing grinding with an accuracy of up to 0.002.

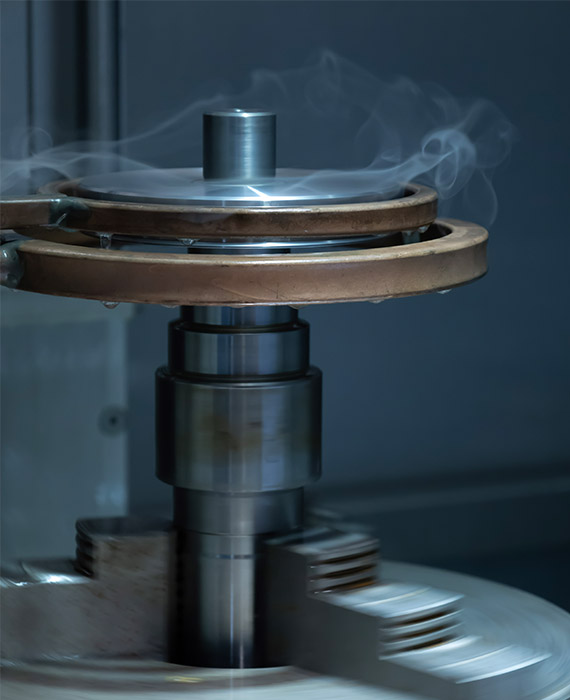

Gear Grinding

We have a KAAP NILES machine, allowing us to produce gears with class 3 grinding precision.

Surface Grinding

The proper selection of the grinding wheel and grinding parameters allows us to achieve surface parallelism below 0.01 mm.

Hobbing (Gear Milling)

We can mill gears up to Module 5 and an outer diameter of 200. It also features post-hardening tooth milling capabilities.

Oxidation

At the customer's request, we offer oxidation of components. This process protects steel parts from corrosion.