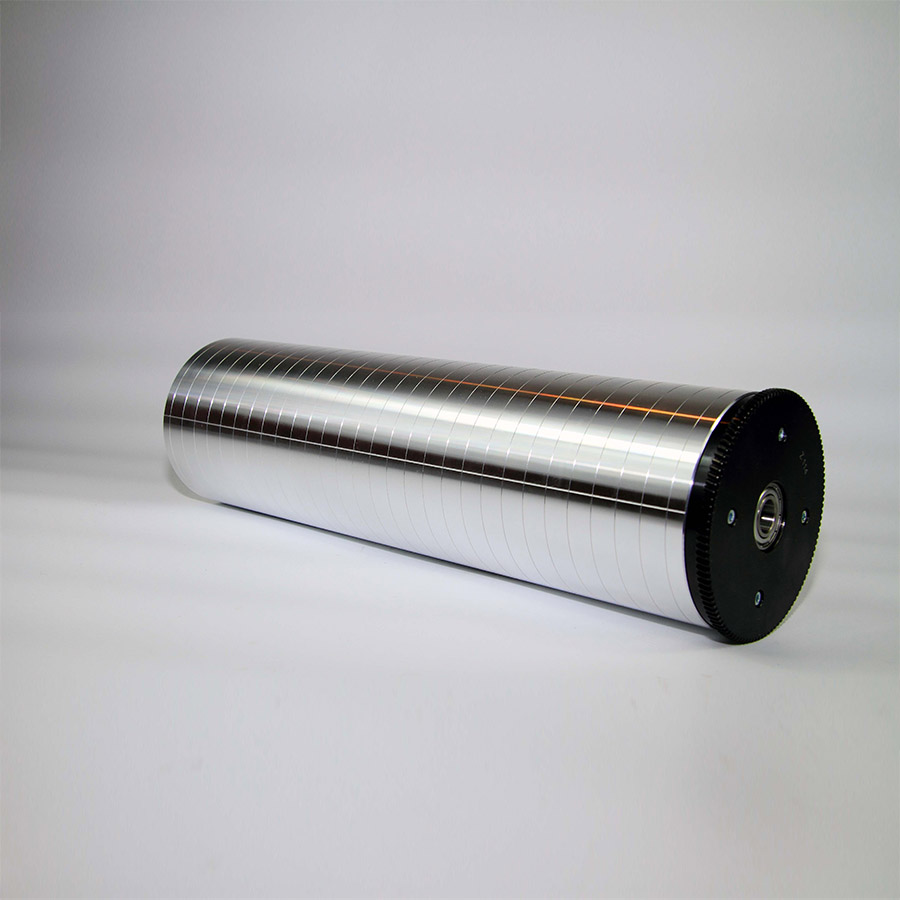

Printing Cylinders

Our printing cylinders are manufactured with exceptional attention to detail, earning recognition not only from individual users but also from machine manufacturers. The precise machining of each detail affects the technical parameters of the finished cylinder, which translates into high print quality, repeatability, and long-lasting, trouble-free operation. We use only high-quality bearings. The applied production technology allows us to achieve axial runout parameters within 0.01mm, significantly exceeding generally accepted standards. If any cylinder component is damaged, we can easily repair it and restore the tool to proper working condition. Special attention should be given to the precision of the gear manufacturing, which fundamentally impacts print quality. Thanks to the use of modern machinery from renowned manufacturers, our gears stand out from others and meet the highest standards.

- Axial runout tolerance within 0.01mm

- Hardened and ground gears DIN 5/6

- Hardened and precisely milled gears DIN 7

- Standard precisely milled gears DIN 8/9

- High-quality materials used

- Surface hardening – anodizing

- Longitudinal auxiliary lines

- Transverse auxiliary lines

- Short lead time